This post was originally published in May 2017 and has been updated in December 2021 for accuracy.

Fiberboard’s Organs

As we know, the human body is made up of many essential components, from the smallest microscopic cell to the largest of organs. The same goes for corrugated boxes, but instead of cells, there are tiny fibers, and instead of organs, there is inner fluting. All components are necessary to have strong and sound structure. Let’s take a look at the anatomy of a box.

The Corrugated Fiberboard

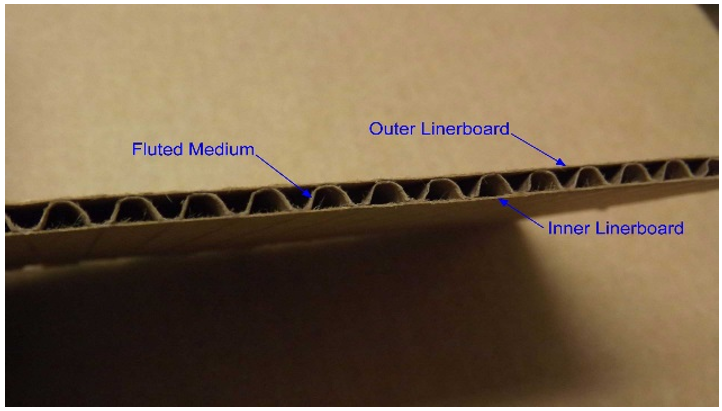

What exactly is a box mostly made of? Corrugated fiberboard. The corrugated fiberboard is essentially the skeleton of the box. Made up by thousands of tiny fibers, it is created by a corrugator. A corrugator is a large machine that combines two different kinds of paper to create cut sheets of corrugated fiberboard. The flat, facing sheets are referred to as the linerboard. Linerboard is a thin fiberboard that makes up the outer layer. Flutes are inner arches attached in between the linerboards with a starch based adhesive. They are designed to resist pressure and bending in all directions.

- Linerboard

- Fluting

Together makes Corrugated Fiberboard

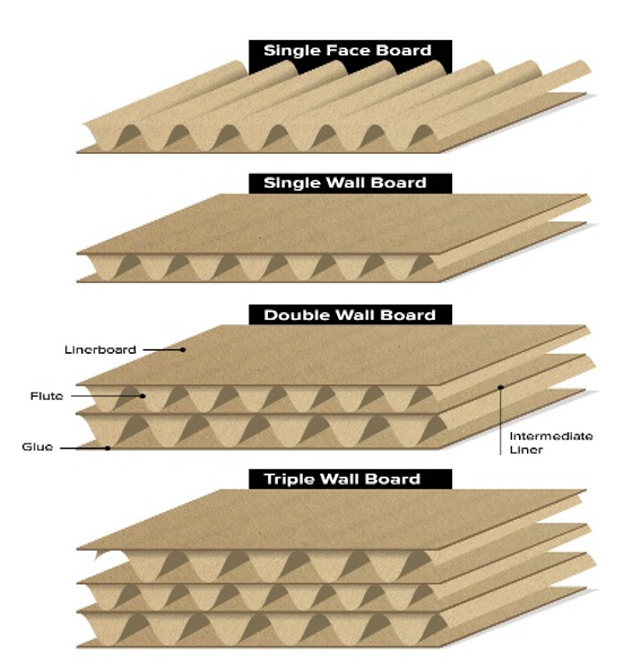

Corrugated Fiberboard can come with various amount of flutes within the linerboard, usually ranging from single wall to triple wall.

Single Face: Consists of 1 linerboard and 1 flute

Single wall: Contains 2 liner boards and 1 flute.

Double wall: Contains 3 linerboards and 2 flutes.

Triple Wall: Contains 4 linerboards and 3 flutes.

In addition the outer liner board can be produced in different colors, usually either brown (often referred to as kraft) or white (often referred to as mottled white or bleached white).

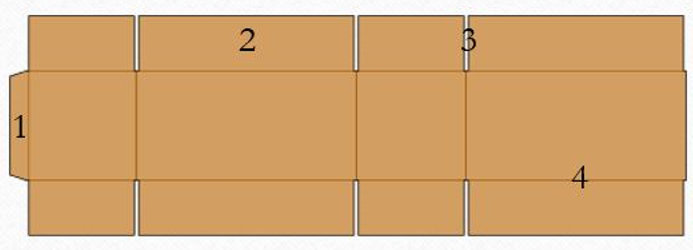

Corrugated Boxes

After the corrugated fiberboard is manufactured, we are ready to load it into the machines to make boxes. Below are the parts of the completed corrugated box.

- Joint- The opposite edge of the box either glued, stapled, wire stitched, or taped together with the last panel to form a box.

- Panel– A “face” or “side” of a box.

- Slots– A wide cut, including removal of a narrow strip of material made in a fiberboard sheet, usually to form flaps and permit folding

- Scores– An impression or crease in corrugated or solid fiberboard, made to position and facilitate folds.

Box Types

RSC – Regular Slotted Container – This is the most common of all box styles. All the flaps are the same length and are ½ the width of the carton, so that they meet in the center of the box when folded.

FOL – Full Overlap – The panels extend all the way to the opposite side and completely overlap. One can order a box with FOL flaps top, bottom or both top and bottom.

Die Cut – A box that is stamped out from a steel rule die that is inserted into a die cutting machine. Die-cut boxes provide greater design options and tighter size tolerances.

As you can see much like us, corrugated boxes can come in many different sizes, shapes, and colors. Here at ICC the Compliance Center we offer many different types of corrugated boxes for shipping dangerous goods.

If you would like to purchase UN packaging or have any questions please contact ICC Compliance Center at 1.888.977.4834 (Canada) or 1.888.442.9628 (USA).

Definitions provided by:

https://www.convergencetraining.com/box-plant-basics-corrugators.html

http://www.empirepackaginganddisplays.com/glossary-terms/

Stay up to date and sign up for our newsletter!

We have all the products, services and training you need to ensure your staff is properly trained and informed.

Custom Packaging Design |

4GV UN Boxes – Variation Packaging |

UN Packaging Posters & Charts |