4GV Packaging has made shipping dangerous goods easier domestically and internationally for shippers with a wide variety of inner containers they need to transport. Previously I wrote a blog outlining the many benefits of 4GV Boxes and compared them to standard 4G boxes.

If 4GV packaging is more suitable for you, how should you go about choosing the correct one? Unfortunately, it’s not as easy as just looking at the inner dimensions of the box and choosing; there are several factors involved in making the correct, compliant decision.

Things to Keep in Mind

Absorbent

Whether you choose a 4GV packaging that requires absorbent pouches and inserts, or if the 4GV packaging requires vermiculite, you must make sure you follow the closing instructions and make sure you look over the required absorbent in the packaging. The inner containers are allowed to vary; however, the absorbent system inside the box must remain the same as it was tested in the lab. In addition, 4GV boxes must have enough absorbent to absorb the total amount of liquids you are looking to ship, so be sure to look at the information on the website; for example, our PK-3SP has a capacity listed as 4 -16 oz containers.

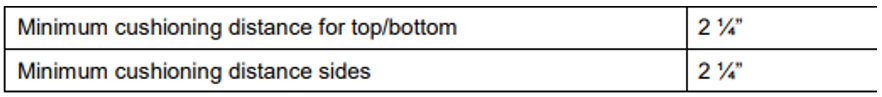

Cushioning distances

If you decide to go with a 4GV that requires loose absorbent material, you have to make sure that you pay close attention to the cushioning distances listed on the closing instructions. If you have an inner container you want to ship, the best way to go about this is to take the dimensions of your inner container (Height x diameter, for example) and make sure the 4GV box you choose is large enough. For example, our PK-24SP 4GV Kit requires vermiculite as the absorbent/cushioning in the box. The closing instructions state that there must be a minimum of 2 ¼” cushioning distance between the top of the inner container and the top, bottom, and sides of the box. The rest of the void space must be filled with vermiculite as well.

So, when you choose the size of your box, you have to make sure you keep in mind that there needs to be extra space for your inner packaging and the absorbent to be compliant and abide by the required amount of cushioning.

Weight limit on the box

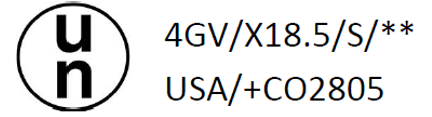

Careful consideration must be made regarding the weight limit on the box. Remember, this is the gross weight allowed, which would include all components. For example, Our PK-10SP kit has the weight rating below.

So, the maximum gross weight allowed in the package is 18.5 KG. However, don’t forget that weight would include the required vermiculite as well as the box itself. So if you had an item that weighed 18.5 KG, followed the closing instructions, and added vermiculite in the box per the closing instructions, it would go over the weight rating and would be non-compliant. You would likely have to choose a 4GV with a higher weight rating if that was the case. The total weight capacity allowed for inner containers for each 4GV box we sell is listed on the website for each individual box; this would give you an idea of how much vermiculite weight needs to go in the box. For example, this is the PK-10SP capacity below:

If you are interested in our 4GV packaging line, please contact us.

Stay up to date and sign up for our newsletter!

We have all the products, services and training you need to ensure your staff is properly trained and informed.

4GV Securepacc™ Complete Shipping Kits |

4GV UN Variation Box – 9.125″ x 9.125″ x 9.5″ |

Vermiculate, Grade A4 – 4 cu ft |

4GV UN Boxes – Variation |